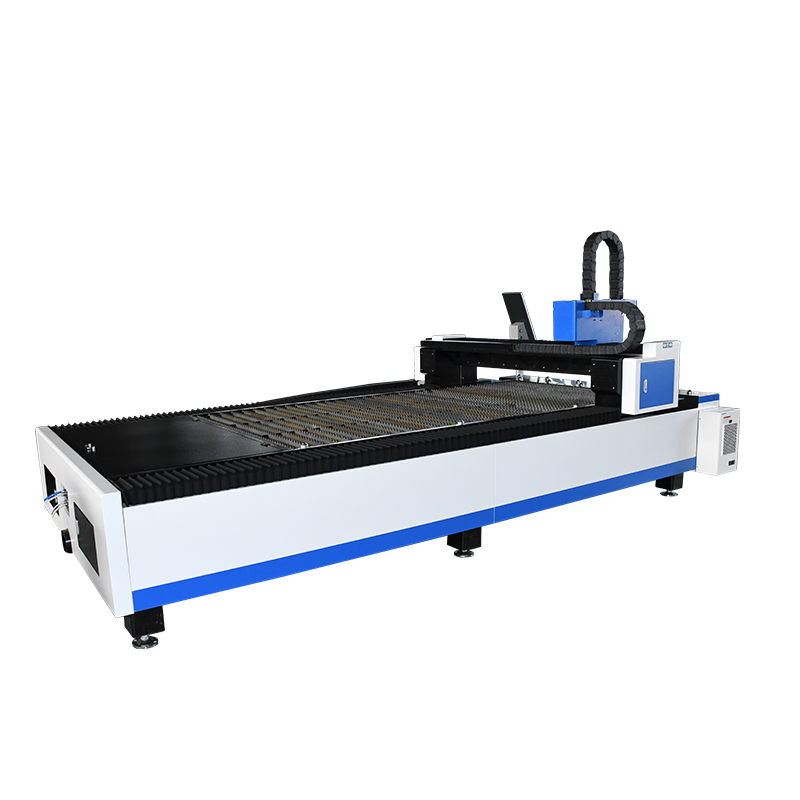

2000W Fiber Laser Cutting Machine

Feature:

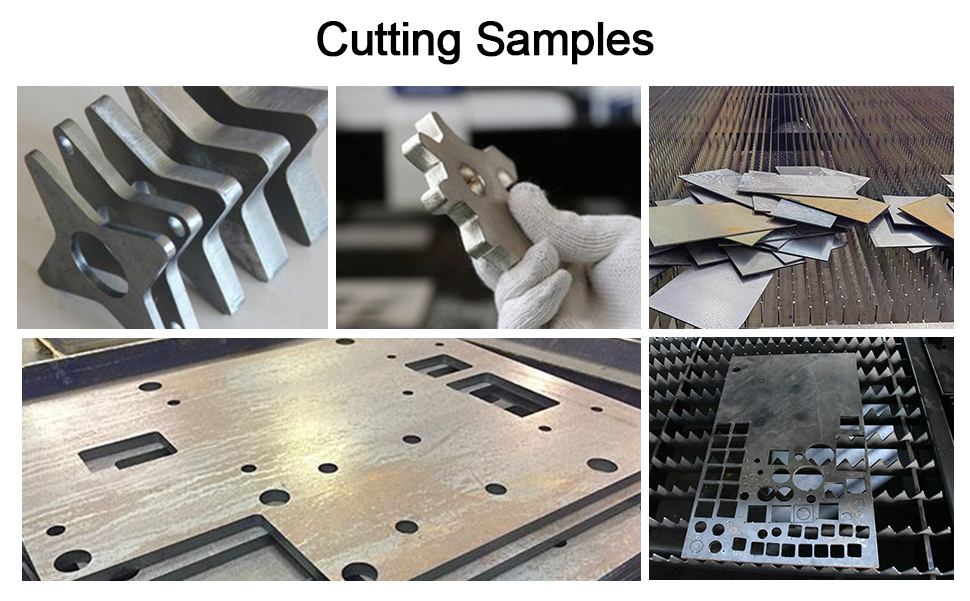

1. Fiber laser cutting machine has high cutting precision, good stability and can work for a long time.

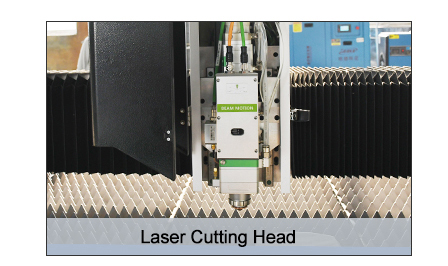

2. The cutting section has good quality and adopts a mechanical following cutting head system. The cutting head follows the height and height of the plate, making the cutting seam smooth and su

itable for planetary or curved plate cutting.

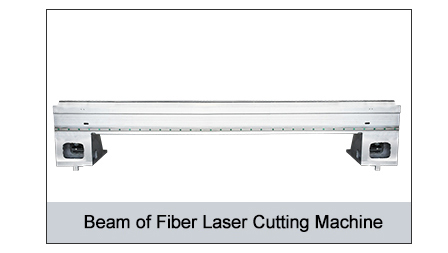

3. Adopt gantry structure and integrated cast beam to achieve higher rigidity, stability and impact resistance.

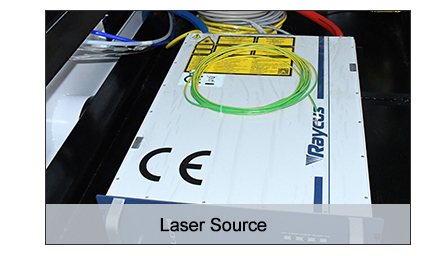

4. High-performance laser source and stable operating system achieve the best cutting effect.

Technical Parameter

Machine model | 3015、4015、4020、6015、6020 etc. |

Cutting Area | 3015、4015、4020、6015、6020 etc. |

Laser source power | 2000W |

Laser Wavelength | 1080nm |

CS cutting thickness | max 5mm/10mm |

SS cutting thickness | max 3mm/5mm |

Interface | USB |

X-Axis | moving speed |

Stroke | 3000mm |

Position Accuracy | ±0.05mm/m |

Repeatability Accuracy | 0.05mm |

Y-Axis | moving speed |

Stroke | 1500mm |

Position Accuracy | ±0.05mm/m |

Repeatability Accuracy | 0.05mm |

Z-Axis | stroke |

Power Supply Requirement | customized |

Continuous Working Time | 24hours |

| Fiber Laser Cutting Head Of Laser Cutting Machine Fiber laser heads have strong advantages in medium-power and large-format fiber laser cutting applications. The interior of the laser head is completely sealed to prevent the optical part from being contaminated by dust. |

| Fiber Laser Source Of Laser Cutting Machine Jolson fiber lasers have the advantages of high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life, and maintenance-free operation. |

| Weter Chille S&A and HANLI brand water chillers for your choice. High cooling rate,which can clean fine clean structure and good joint performance |

| High Precision Bed High quality square tube weld-ing andthree pass weldingprocess areadopedwhich aresturdy and durble. The struc-turalmaterials are analed at high-tem-perature to eliminate internalstress,sothat the machine bed canmaintaingood mechanical proper-ties such astensile strength, tough-ness, hardnessand deformation resis-tance. |

| High Precision Beam It is manufactured according to aerospace standards and has the strongest hardness of all beams afteraging treatment. lt has good toughness,good rigidity and high precision. |

| Servo Motor Imported from Japan, using top brands such as Yaskawa and Fuji. X, Y, and Z axes use high-power motor systems. High precision, good cutting effect, fast cutting speed. |

| Reducer Smooth operation. Low noise. High output torque. High speed ratio. |

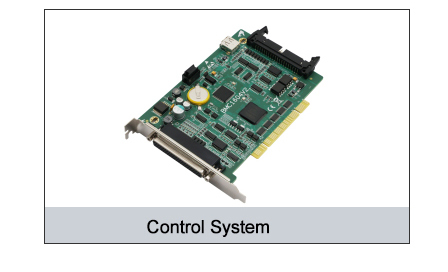

| Control System Easy to use. Various file editing functions. Support remote control. Real-time alarm and protection. |

Application industry

Fiber laser cutting machine adopts gantry motion structure, linear guide rail, screw drive, AC servo motor and driver, vacuum system (both sides), etc., and the one-time processing area is 3m*1.5m. The design is advanced and reliable, and the key components are from well-known domestic and foreign brands. In particular, the electrical control system adopts the professional laser CNC system of a German company. This dedicated laser CNC system has the advantages of high integration, better control accuracy, and more stable operation. Therefore, in addition to meeting the requirements for cutting carbon steel plates, it can also meet the requirements for cutting stainless steel plates, aluminum alloys, and copper alloys. and other materials.