1500W Fiber Laser Cleaning Machine

Product description

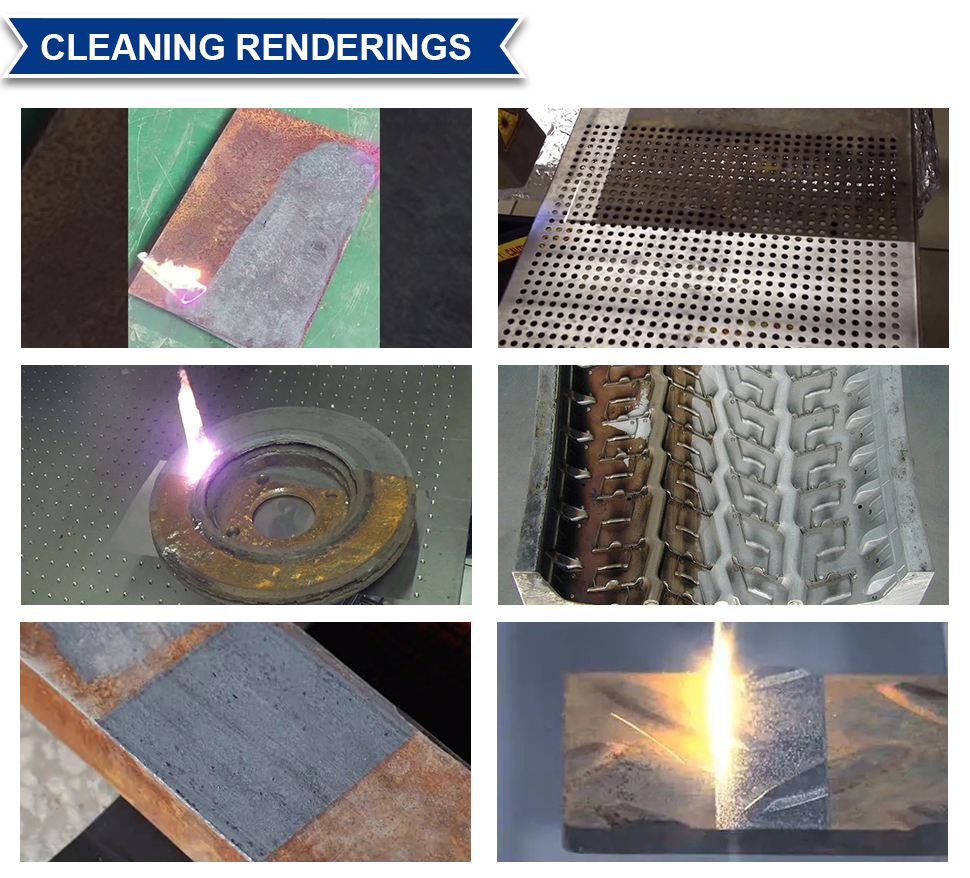

Laser cleaning machines are used for metal surface rust removal, surface paint removal, surface oil stains, stains, and dirt cleaning; surface coating. Non-contact cleaning does not damage the parts matrix, and can achieve precise location and size selective cleaning without any chemical washing liquid or consumables.

Application

1. The objects or materials processed by laser cleaning machines include molds, wheels, guide rails, pistons, aluminum alloys, titanium alloys, hot-rolled steel, etc.

2. Metal surface rust removal, surface paint and paint removal treatment, surface oil stains, stains, dirt cleaning, surface coating cleaning, welding surface, spray surface pretreatment, stone statue surface dust and attachments cleaning, rubber mold residue cleaning.

3. Laser cleaning machines are suitable for rail, shipbuilding, auto parts, printing industries, rubber molds, high-end machine tools, tire molds, environmental protection industries, etc.

Features

1. "Green" cleaning does not require chemicals and cleaning agents and will not cause pollution to the environment.

2. Non-contact, no damage to the substrate, and no deformation.

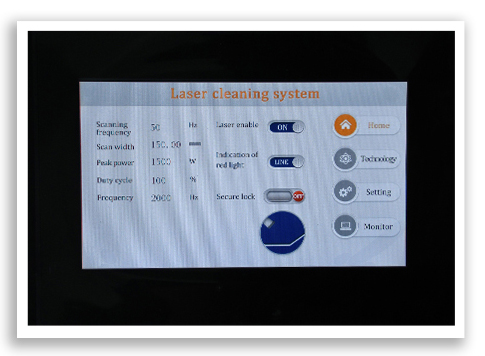

3. Wireless control enables parameter setting and light control from a distance, and parameters can be updated at any time.

4. Red light auxiliary focus technology can adjust the focus position according to different field lenses to achieve precise cleaning.

5. Monitor the status of the entire machine in real time to facilitate troubleshooting and problem solving to ensure stable operation of the system.

6. Laser cleaning is highly efficient, saving time and labor costs. Simple operation and high safety.

7. Small size and light weight. The structure is stable, wear-resistant, shock-proof and fall-resistant.

Name | Parameter |

Laser Power | 1500W 2000W 3000W |

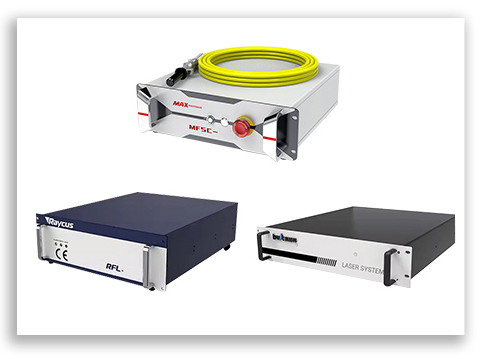

Laser Source | Raycus /Max/Optional |

Working Model | Continuous/Modulated |

Cleaning Mode | Straight/Optional |

Wavelength | 1080nm |

Laser Swing | Simple |

Laser Width | 10-300mm |

Cooling Model | Water Cooling |

Cable Length | 10m/15m |

Working Environment | Temperature 10~40℃, humidity <70%,no condensation |

Working Voltage | 220V/380V, 50/60Hz |

Weight | <180kg |

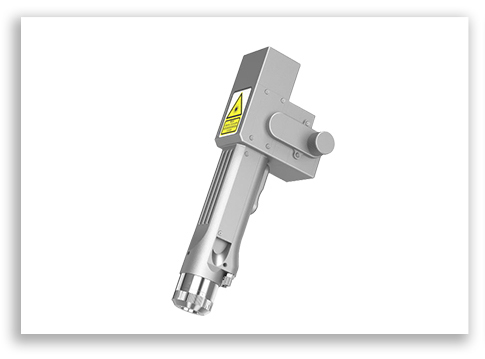

| Laser Cleaning Head Cleaning width: up to 300mm |

| Laser Source Raycus Max BWT brand laser suorce can becustomized accord-ing to customers. High stability,Long lifespan, 100,000+hours |

| Water Chiller S&A and HANLI brand water chillers for your choice. High cooling rate,which can clean fine clean structure and good joint performance |

| Touch Screen System Intelligent control system, touch screen easy to set parameters.Has a variety of laser cleaning mode to meet different needs. It can support the languages of at least 16 countries. |

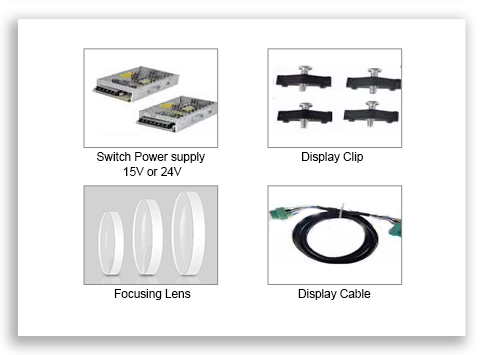

| Accessories Random Accessories |

Shandong Jolson Machinery Co., Ltd. located in Jinan. Our corporation specialized in the field of laser industrial for many years, committed to providing professional laser solutions in industrial application, including fiber laser welding machine, laser cleaning machine, laser cutting machine, and other accessories like laser source, laser optic cable, laser welding head, laser cutting head, water chiller and so on. More importantly, we provide whole-heartedly customers with laser equipment upgrading, laser cutting head maintenance, whole machine checking and maintenance, and also laser optic cable replacing service (own welding machine).

Equipped with 18 workers in production (within 5 senior maintenance engineers and 3 quality inspectors) and mature customer services team, we provide 24h online services and guidance and try our best on solving whether installation, maintenance or upgrading requirements (except the core value parts which means repairing cost is too high), and also guarantee on providing customers with the most cost-effective solutions which also suit for our own responsibility. We have served and exported many countries, like the United State, Spain, France, Germany, Australia, India, Paraguay and so on and exceeded our customers expectations.